*XOCO (pronounced SHO-ko) is slated to open at 449 N Clark St this month.

XOCO's chocolate

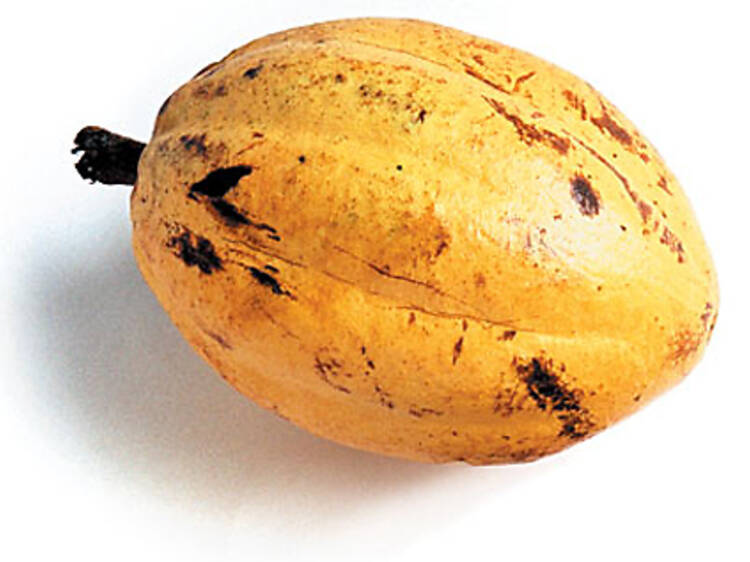

There will be pastries and tortas and churros at Rick Bayless's new street-food shack, XOCO*. But there's one thing the restaurant's chefs are doing that nobody else in the city can touch: They're making chocolate from raw cocoa beans. Here's how it happens.

Discover Time Out original video